Colloidal antimony pentoxide is an antimony flame retardant product developed by industrialized countries in the late 1970s. Compared with antimony trioxide flame retardant, it has the following application characteristics:

1. The colloidal antimony pentoxide flame retardant has a small amount of smoke. Generally, the lethal dose LD50 of antimony trioxide to rats (abdominal cavity) is 3250 mg/kg, while the LD50 of antimony pentoxide is 4000 mg/kg.

2. Colloidal antimony pentoxide has good compatibility with many organic solvents such as water, methanol, ethylene glycol, acetic acid, dimethylacetamide and amine formate. Compared with antimony trioxide, it is easier to mix with halogen flame retardants to form various high-efficiency composite flame retardants.

3. The particle size of colloidal antimony pentoxide is generally less than 0.1mm, while antimony trioxide is difficult to refine into this particle size. Colloidal antimony pentoxide is more suitable for application in fibers and films due to its small particle size. In the modification of flame retardant chemical fiber spinning solution, adding gelatinized antimony pentoxide can avoid the phenomenon of blocking the spinning hole and reducing the spinning strength caused by adding antimony trioxide. When antimony pentoxide is added to the flame retardant finishing of the fabric, its adhesion on the surface of the fabric and the durability of the flame retardant function are better than those of antimony trioxide.

4. When the flame retardant effect is the same, the amount of colloidal antimony pentoxide used as a flame retardant is small, generally only 30% of antimony trioxide. Therefore, the use of colloidal antimony pentoxide as a flame retardant can reduce the consumption of antimony and further improve various physical and machining properties of flame retardant products.

5. Antimony trioxide is used for flame-retardant synthetic resin substrates, which will poison the Pd catalyst during electroplating and destroy the unplated plating pool. Colloidal antimony pentoxide does not have this shortcoming.

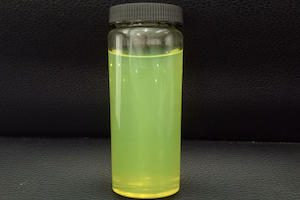

Because colloidal antimony pentoxide flame retardant has above characteristics, it has been widely used in flame retardant products such as carpets, coatings, resins, rubber, chemical fiber fabrics in developed countries. Engineers from the Technology R&D Center ofUrbanMines Tech. Limited found that there are many preparation methods for colloidal antimony pentoxide. At present, hydrogen peroxide is mostly used for preparation. There are also many kinds of hydrogen peroxide methods. Now let’s take an example: add 146 portions of antimony trioxide and 194 portions of water to the reflux reactor, stir to make a uniformly dispersed slurry, and slowly add 114 portions of 30% hydrogen peroxide after heating to 95℃,make it oxidize and reflux for 45 minutes, and then 35% purity colloidal antimony pentoxide solution can be obtained. After the colloidal solution is cooled slightly, filter to remove insoluble matter, and then dry at 90℃, the white hydrated powder of antimony pentoxide can be obtained.Adding 37.5 portions of triethanolamine as a stabilizer during pulping, the prepared colloidal antimony pentoxide solution is yellow and viscous, and then dry to obtain yellow antimony pentoxide powder.

Using antimony trioxide as raw material to prepare colloidal antimony pentoxide by hydrogen peroxide method, the method is simple, the technological process is short, the equipment investment is low, and the antimony resources are fully utilized. One ton of ordinary antimony trioxide can produce 1.35 tons of colloidal antimony pentoxide dried powder and 3.75 tons of 35% colloidal antimony pentoxide solution, which can promote the production of flame retardant products and broaden the broad application prospects of flame retardant products.